Mastering Product Manufacturing Information (PMI) Data for Metrology and Quality Control by

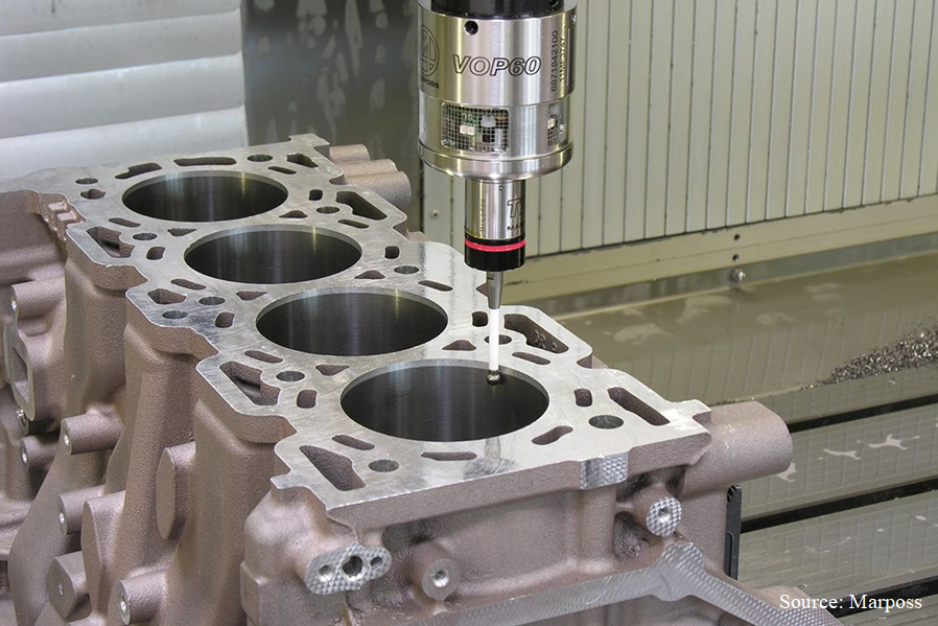

using Touch Probe Measurements

The world of CNC machining is constantly evolving, with advancements in technology continuously pushing the boundaries of precision and efficiency. One such innovation that has demonstrably transformed the industry is CNC probing software. This powerful tool empowers machinists to unlock a new level of control and automation, streamlining workflows and ensuring exceptional part quality.

In traditional 2D drawing-based workflows, many tasks are processed manually, taking time away from skilled engineers that could be better spent. Manufacturing and quality control engineers manually enter and interpret Geometric Dimensions and Tolerances into their Coordinate-measuring machine (CMM), Computer-Aided manufacturing (CAM), or Computer-Aided Inspection (CAI) software. Depending on the complexity of the part, this can take days, if not weeks.

Additionally in quality assurance, a significant amount of idle time is generated by the programmed movements of the touch probe between the different measurement positions, especially which complex components.

INOVAITEC developed CAM Inspection software that includes methods to improve the planning of alternative paths between measurement points or edges of the workpiece. To realize this approach, a genetic optimization algorithm improves the order of the individual points and edges to be measured.

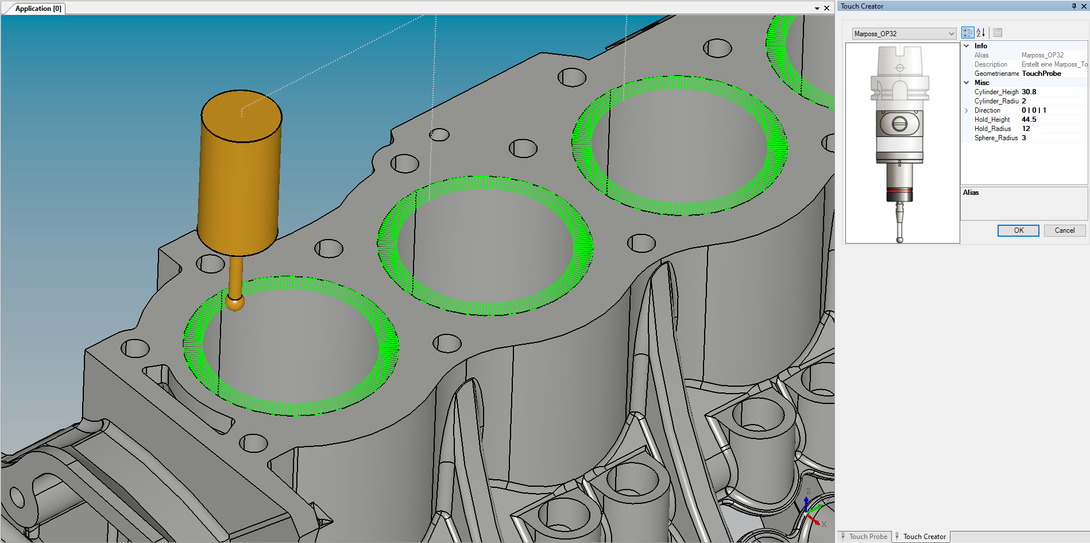

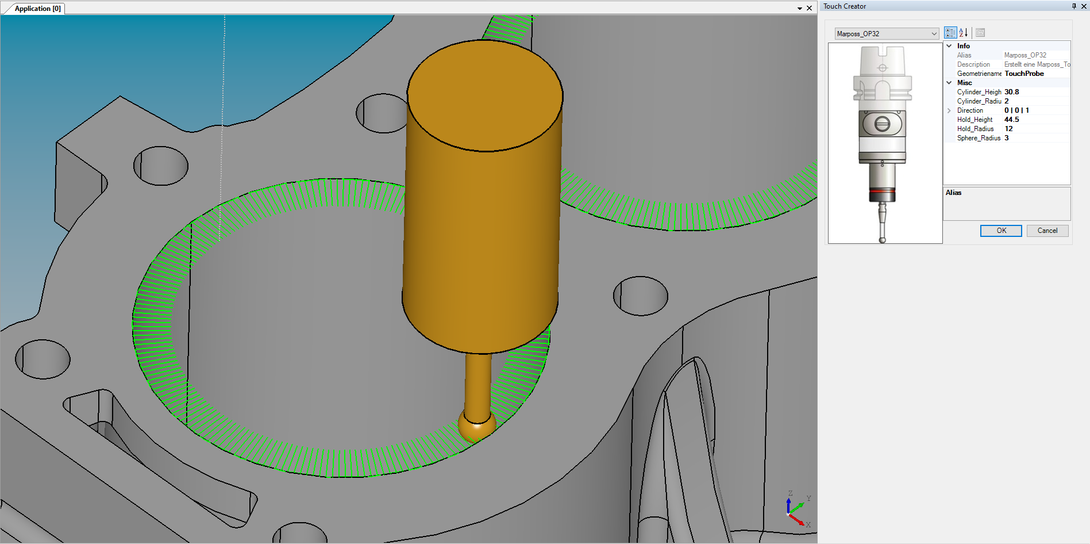

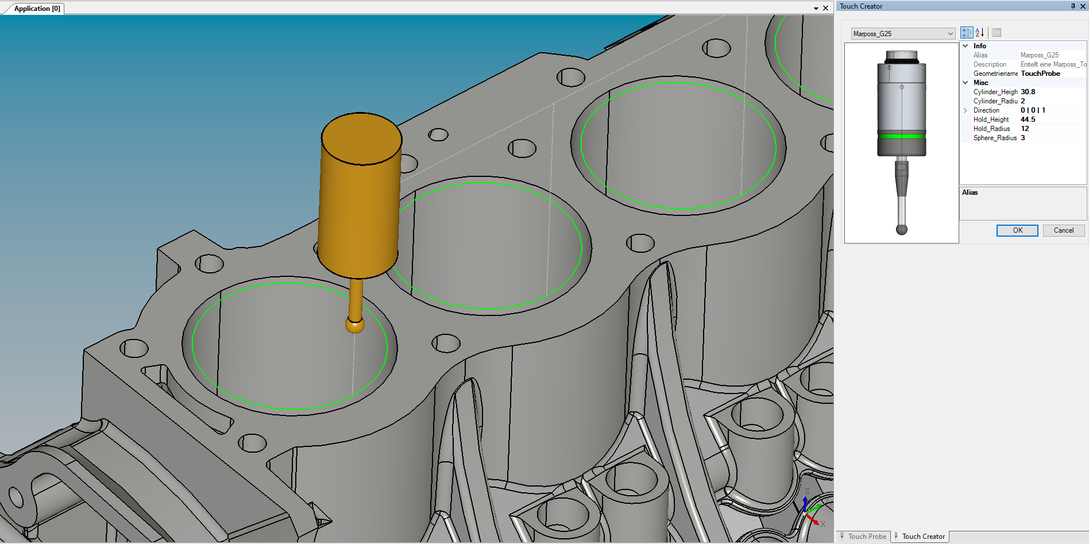

The software enables state-of-the-art 3D visualization and processing of massive data used in modern metrology. The selection of the points, edges, and surfaces to be measured is typically performed by the user. For the automatic optimization of the measurement process, the sequence of operations is arranged in a way that the traveling distance of the touch probe reaches a minimum. In this way, a time-optimal path for the measurement of the component is generated.

As an additional feature, there are two different measuring modes: The first commonly used mode for tactile measurements is based on a sequence of measurement points which are processed one after another. The second mode generates continuous lines/curves to scan a defined profile of the workpiece.

The first mode: sequence of measurement points

The second mode: uses continuous lines or curves to scan a defined profile

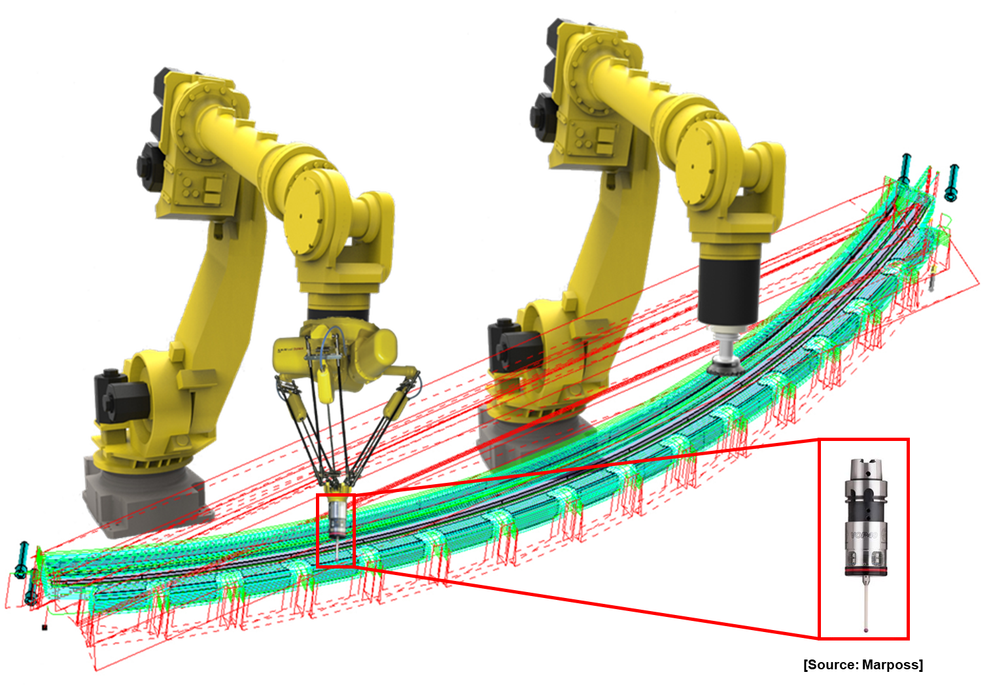

The software has already been used in combination with the MARPOSS G25 industrial touch probe during research projects (Field of Robotics). According to the fact, that the G25 touch probe is able to acquire continuous measurement profiles, these tools can be used to plan and operate measurements to determine the surface quality of complex structural components for the aerospace industry.

Field of Robotics: Approach for a work around concerning the reduced positioning accuracy of a robot in motion

- A G25 touch probe is mounted on an industrial Hexapod robot to scan the contours of components (fixed installation at the robot's end effector)

- The industrial robot arm approaches each measuring feature. During a hold time the fast Hexapod completes the measuring task with high relative accuracy

Industries: Aerospace Automotive Manufacturing Metrology and Quality Control CNC-Machinery Industry 4.0

Contact

Do you have more questions?

Give us a call on: +49 (0) 176 310 693 62

or send an email to: info@inovaitec.com

We will do our best to answer your questions!